Top four obstacles to overcome when implementing predictive maintenance

Predictive maintenance has plenty of positives and can help you avoid expensive repairs as well as reduce the downtime of machines. But it’s not quite so straightforward to implement and many businesses struggle to overcome certain problems. These obstacles include:

Lacking knowledge

If you don’t know what predictive maintenance is or have no idea about how to implement it, then it’s going to be difficult to introduce. However, you can use tools and software like MATLAB to help you set up your predictive maintenance plan in the beginning. This reduces the need for extensive training that takes more time and money, leaving your engineering team to focus on what matters most.

Having little data

Predictive maintenance depends upon data to function. Because the system is made up of algorithms that learn from previous data, it’s necessary to collect it if you want to produce accurate models. Machine sensors are good sources of this data, but you’ll need to log it at regular intervals. It’s important to avoid having systems set to only record crucial data when errors occur, as this means valuable information will be lost.

Not having failure data

Although it’s important to have more than just failure data, having data about when and why certain functions fail is incredibly important. If you don’t have failure data, then you can use simulation software like Simulink so that you can collect it. However, once you’ve done this, it’s best to set up a programme to collect the data in real-time to ensure that it’s completely accurate for future use.

Inability to predict failures

Understanding failures is one thing, but predicting them is a whole other story. To do this, engineers must engage with their data, set clear goals and develop a reliable framework for testing purposes. Applying knowledge in this way will, over time, allow them to better predict failures and prevent them before they occur.

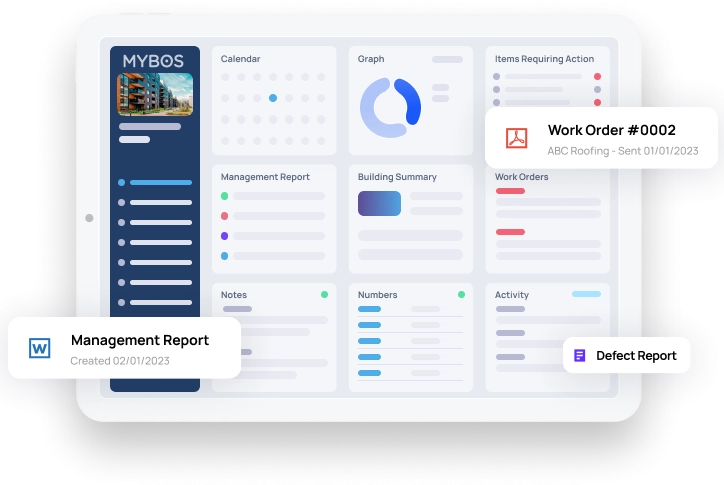

How can MYBOS help?

Calendar scheduling

The MYBOS app can help you to stay organised and keep track of all your preventative maintenance measures. The interactive calendar helps you to store data, schedule data logging activities, and store instances of failures. Displayed in an attractive, user-friendly way, you’ll never have to rely on another dull spreadsheet again. It’s easy to colour code, allowing you to pick up information quickly and find the details you’re looking for without sifting through all your entries.

Organisation and alerts

The handy order list is also ideal for keeping on top of maintenance that needs to be carried out. Fixing problems before they manifest into bigger ones will aid your preventative maintenance efforts and the best part is you’ll be notified automatically. Use the app to receive SMS or e-mail alerts about new jobs and how current ones are progressing to stay on top of your preventative maintenance.

Reports and charts

Data can be tough to analyse if it’s just a string of numbers, but MYBOS gives you the power to turn all this into a chart or report of your choosing. This makes it much easier to present predictive maintenance to other members of your team as well as store the history of your system in a more user-friendly way.